Health care has become more sophisticated thanks to new technologies. Repairing new biomedical devices can pose a severe problem in the complicated world of medical gadget manufacturing. The highly controlled biomedical market is now subject to a number of compliance issues. These services include the maintenance and repair of scientific instruments.

These services ensure client safety. These services provide preventive maintenance that ensures the proper functioning of all medical devices. Additional support is also provided at the equipment selection, acquisition, and integration stages. Medical cable manufacturing is, however, closely linked to it.

An overview

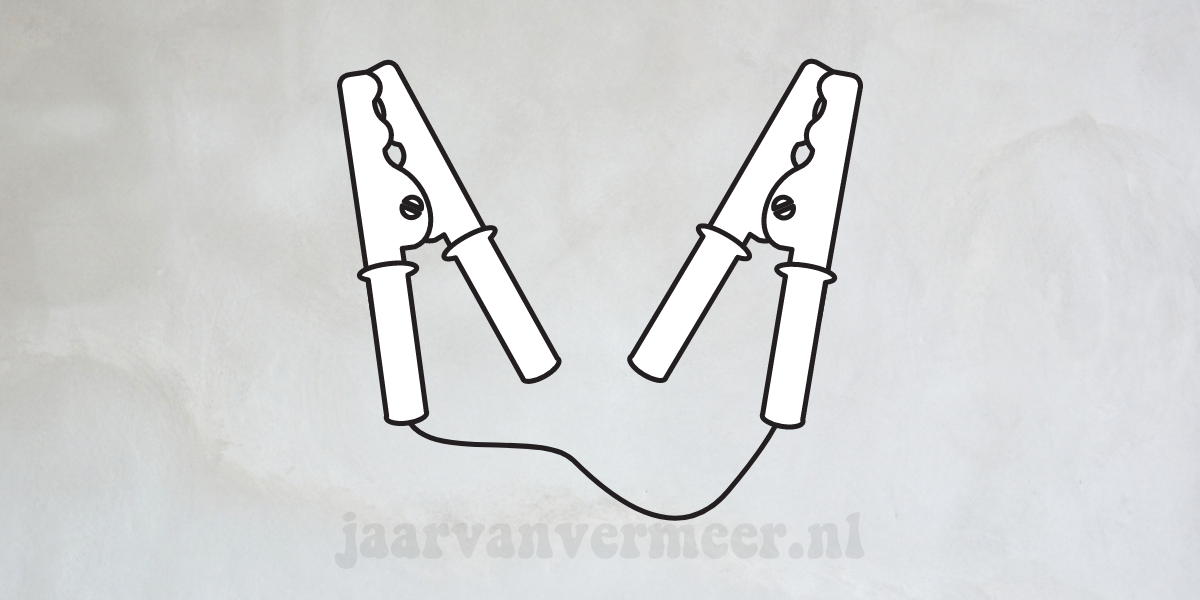

Expertise in medical device manufacturing requires knowledge of various assembly strategies and methods. Many procedures are needed to produce complex and unique medical devices. Medical cable manufacturing is a vital part of this process. Artificial bonding products can also be offered by companies that are medical device manufacturers. Manufacturers of medical cables can design, manufacture, and operate medical wires.

Things to Know

Today’s medical market is a vast marketplace that includes a large number of instruments and devices. This requires a lot of complex circuitry and cords assemblies. Medical cable manufacturers can assist health centers by customizing the cords assemblies to their specific needs. These cords are sometimes used to treat patients and are usually disposable. They are only used for one patient and then it is discarded. Non-reusable cables are also less expensive than other types. These cables are of very high quality because they allow for the placement of medicines and other treatments.

To avoid tangles and to ensure that the nurses or medical professionals are not at risk, the wires connecting to instruments must be arranged in a single unit. Because of this, certain dangers can be avoided.

The secrets of medical cable assembly

* The wires are not brittle and unyielding. Any sudden pull or improper handling will not cause damage to the product.

* They are placed in premium wires that connect to lose wires and act as an excellent defense against cables getting damaged.

These wires are used to transfer and transmit energy. We should be careful when purchasing them. Because of the potential dangers it poses, we should only buy them from a reputable manufacturer.

These wires are made of insulators to avoid shock to clients. They provide little electrical power.

* Medical cable companies are able to use them in a specific way to support many types of instruments.

The increasing competition has made the current economy a boon for the cable assembly industry. Due to the importance of the work involved, the manufacturers that offer this service must follow specific rules. It is easy to get the assistance you need by following the correct pattern for cords assembly. If a medical product has been awaiting release for a long time, it can be quickly introduced.

Cable assemblies are used to connect laboratory and pharmaceutical instruments within a hospital or diagnostic center. This coat protects the cables from abrasions. This coating ensures longer mechanical life and lower frictional surfaces.

Summary: Medical cable manufacturing is booming with advancements in medicine. It is the best solution for biomedical instrumentation.